How to detail a wall plate: a sift through the guidance

Photo by Iván Rivero from Pexels

It’s less straightforward than you might think

A wall plate is a common detail in small to medium-sized buildings in the UK. So common that you might expect its design to be straightforward and for any associated guidance to be simple.

As with most things, the reality is more complicated. Plenty of technical guidance is available but it isn’t comprehensive and can be confusing. Occasionally, it is wrong. Surprisingly, some guidance advises doing things according to ‘local practice’ - whatever that means - rather than providing recommended solutions.

In this post, I want to explain wall plate detailing issues and review the guidance* so you can confidently develop details that comply. The scope is limited to wall plates on masonry walls supporting timber roofs, although wall plates are used in other situations, such as on masonry sleeper walls supporting timber floor joists or in timber framed construction.

I also want to illustrate how an in-depth look at a basic detail like this will help you begin to develop your expertise in building technology. I’ll look at other common details in future, but for now, wall plates seem as good a place to start as any.

The post, which is a 15 min read, covers the following topics:

the purpose of a wall plate

what size should a wall plate be?

how should a wall plate be installed?

holding down and lateral restraint

is the wall plate structural?

my preferred solution

summary

Note *: In developing the post, I’ve referred to relevant guidance, textbooks and trade literature, for which a summary and brief commentary can be found here.

The purpose of a wall plate

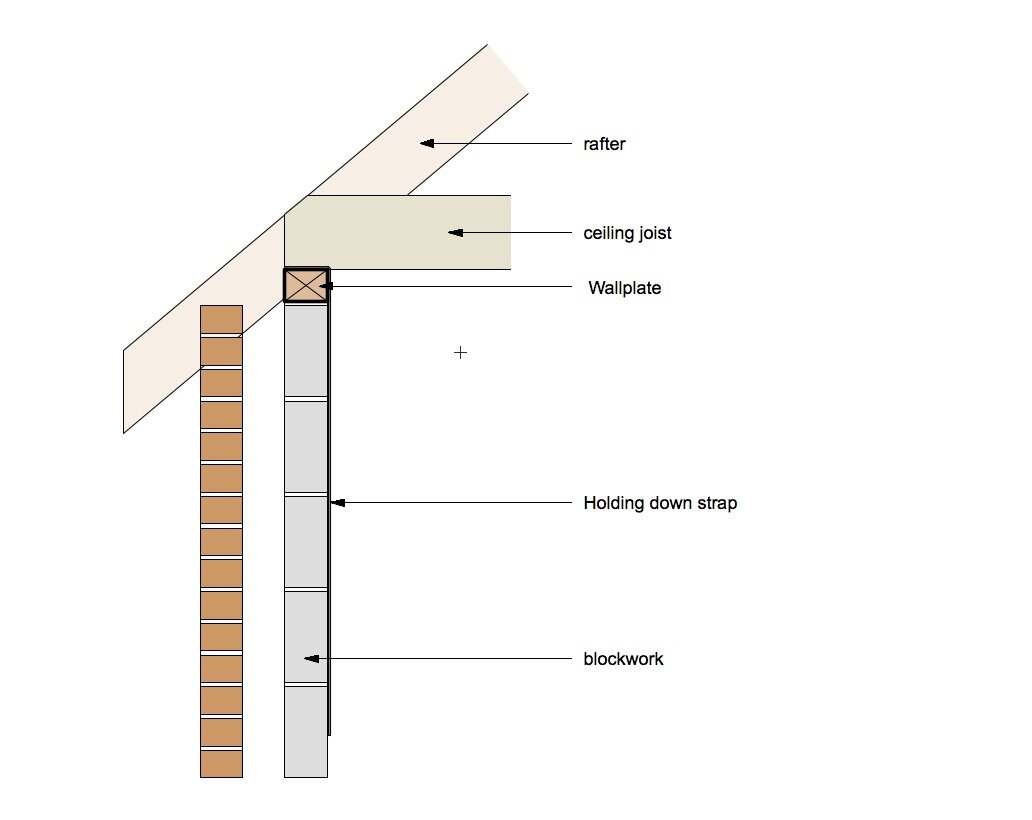

Timber wall plate on blockwork inner skin supporting a timber roof

The UK's most common form of building construction comprises a timber pitched roof supported by masonry walls. A timber wall plate is installed at the top of the masonry wall to which the roof structure is fixed.

During construction, the completion of the masonry wall doesn’t just mean a change in structure from wall to roof; it also marks a change in trades, from bricklayers to joiners.

When the joiners start work, they want confidence that they’re working on something correctly ‘lined and levelled’ and that there is a simple and quick method for fixing the roof timbers.

In most timber roof structures, all rafters and ceiling joists are the same and have their ends cut to identical profiles. For the joiners to work efficiently, they work in 'production-line’ mode, first cutting all of the roof timbers at ground level and then fixing them in position quickly, in a repetitious sequence.

Although installing the wall plate takes time, doing so has the advantage that the roof structure can be constructed accurately and efficiently.

Some guidance documents also refer to the wall plate as a means to distribute the loads from the roof into the wall, but this is misleading. While it is true that the roof loads have to pass through the wall plate, masonry has a higher compressive strength than softwood, and hence the wall does not need the wall plate to spread the load; that’s not what it’s for.

Note: In timber-framed walls, the wall plate has to span between the vertical timber studs and therefore has more of a structural role in distributing the roof loads into the wall.

Rafters cut to wall plate. Wall plate fixings and ceiling joists yet to be installed. Image: Raise Architects

What size should a wall plate be?

When I started working, I was advised by someone (I don’t remember who) that wall plates should be from softwood timber with a section size of 50x100mm. That is what I specified until, years later, a building inspector told me that the section size should be 75x100mm.

This is a good example of what often happens in building design and construction; we follow what we’ve been told without understanding why. We’re just grateful for advice from someone who speaks with authority.

But do we question that advice and bother to look at the technical guidance on the subject? We should, but often we don’t.

Here’s a summary of guidance on wall plate size:

Approved Document A doesn’t give any advice on wall plates at all. This is an interesting fact and means that wall plates are not a specific requirement of the Building Regulations.

However, they are a common solution, and if you do intend to install a wall plate, Approved Document A allows the option to refer to BS 8103-3, which includes the following note:

‘In England & Wales, it is normal for wall plates to have a basic thickness of 38mm, whilst, in Scotland, thicknesses of 25mm or 47mm are typical. These thicknesses are acceptable for this Part of BS 8103. ’

Hence, this British Standard doesn’t suggest a width; as far as depth is concerned, it only refers to what is done in practice. It does say, however, that the quoted thicknesses are acceptable, but it does so without any explanation. Why a 25mm thick wall plate is acceptable in some parts of Scotland but not elsewhere remains a mystery.

NHBC Standards 2020 (which apply to the UK) is roughly similar in stating that wall plates should be ‘38x100mm or in accordance with local practice.’

Barry: Construction of Buildings Vol 1 states that ‘it is usual for wall plates to be 75x100mm.’

Chudley & Greeno: Construction Technology has wall plate diagrams consistently labelled ‘50x100mm’.

Armed with this variety of guidance, how do you correctly size the wall plate?

Firstly, there isn’t a universally correct answer. In England & Wales, if you specified a 38x100mm wall plate or thicker, you would appear to comply with the British Standard and NHBC requirements.

So why would you specify anything thicker?

The wall plate has to be jointed and fixed to the wall (as described below), and having a more substantial piece of timber makes this easier. I also think that larger, heavier timber makes it easier to achieve ‘line and level’, especially when the wall plate is exposed to the elements and therefore gets wet and tends to warp.

One additional point worth noting is that none of the guidance documents refer to wall plate sizing relative to the size of the building. The size of the wall plate is the same, whatever the size of the building.

A 75x100mm wallplate shown for a single space garage, a larger outbuilding and a single-storey dwelling

How should a wall plate be installed?

Installation guidance appears in several documents:

NHBC Standards 2020 says that wall plates should be :

bedded to line and level

fixed using nails or straps

a minimum of 3m or extend over at least three joists, rafters or trusses

joined using half-lapped joints, including at corners

BS 8000-5:1990 concurs with that guidance and adds that half-lap joints should be a minimum of 100mm long, twice nailed and advises that wall plates should be fixed according to the following table (Table 17):

BS 8103-5 also advises that lap joints should be 100mm long, twice nailed and that butt joints with proprietary fixings are also acceptable.

BS 8000-3: 2001 advises the following:

Lay wall plates true to level on a solid bed of mortar.

None of the guidance provides an explanation, so I will add some here.

The timber wall plate needs to be bedded on mortar to provide full and continuous support from the wall (i.e. without any gaps that would allow the timber to flex). This also allows the wall plate to be set at an accurate level.

The joiners will cut the wall plate timber, and the bricklayers will bed it on mortar to line and level. The lap joint fixings and the fixings of the wall plate to the wall can’t be installed until the mortar has set. The joiners will normally install these fixings.

The requirement for relatively long lengths of wall plate is to minimise the number of joints, which will, in turn, aid line and levelling.

Table 17 of BS 8005: 1990 provides guidance on fixing the wall plate to the wall. It suggests using nailing when fixing into blockwork, otherwise by using light gauge metal straps with a 150mm leg length down the face of the wall. I’ve never seen either of these methods used in practice and would suggest that it could be done with various conventional fixings suitable for connecting timber to masonry. For instance, using frame fixings through the centre of the wall plate into the masonry.

Often, wall plates are not mechanically fixed to the wall - other than by the straps installed for holding down purposes.

Holding down and lateral support

The issues of holding down the roof and lateral support to the wall are not very well understood and can be confusing. Approved Document A doesn't help by illustrating vertical strapping (required to hold the roof down) in a diagram titled 'Diagram 16 Lateral support at roof level'.

In strong winds, it is possible for pressures to exist that can lift roof structures. In such instances, the wind pressure is negative, and the roof structure is sucked upwards (rather than blown off). The roof's weight is often sufficient to overcome the uplift force, and there isn't a problem. Where the weight is insufficient, the roof structure must be strapped to the walls to provide the necessary resistance.

Image: David Mankelow (Yorkshire Post)

Hence, the walls support the roof's weight and hold it down when necessary. The walls need support when subject to horizontal forces, such as horizontal wind pressure - which can be positive or negative. At the top of the wall, the roof structure provides the necessary horizontal support by transferring the horizontal loads from the wall to other structural elements. In this case, the wall is said to be 'laterally supported' by the roof structure. The collapse of gable walls is a common event that illustrates the need for lateral support. Unless a gable wall is connected adequately to the roof structure, the gable triangle is susceptible to being blown over - or, more likely, sucked out - by strong winds.

Image: Leicester Mercury

Approved Document A attempts to summarise the more extensive content of BS 8103-1: 2011 and confuses things in the process. BS 8103-1: 2011 is marginally better in providing clear guidance for the strapping required to hold the roof down and the lateral support of gable walls. However, it is silent on the lateral support of flank walls, such as in a typical eaves detail with a wall plate.

There are two potential conclusions:

Either the authors of these documents considered that the provision of the vertical strapping is sufficient also to provide the lateral support connection - something that is unlikely given a) that's not what it's for and b) both documents permit the omission of the vertical strapping in situations where the weight of the roof is assessed to be sufficient to overcome the effects of any wind uplift.

Or they considered that mechanical connections for lateral support are not required along the eaves, perhaps because they are typically not provided in practice, and this doesn’t lead to problems. The implication is that there is sufficient connection provided by friction between the wall plate and the wall - an effect proportional to the roof's weight.

3d view of wall plate showing typical fixings

My preferred solution

This is how I detail and specify a timber wall plate for a masonry wall (brick or block) supporting a timber roof in house construction up to three storeys:

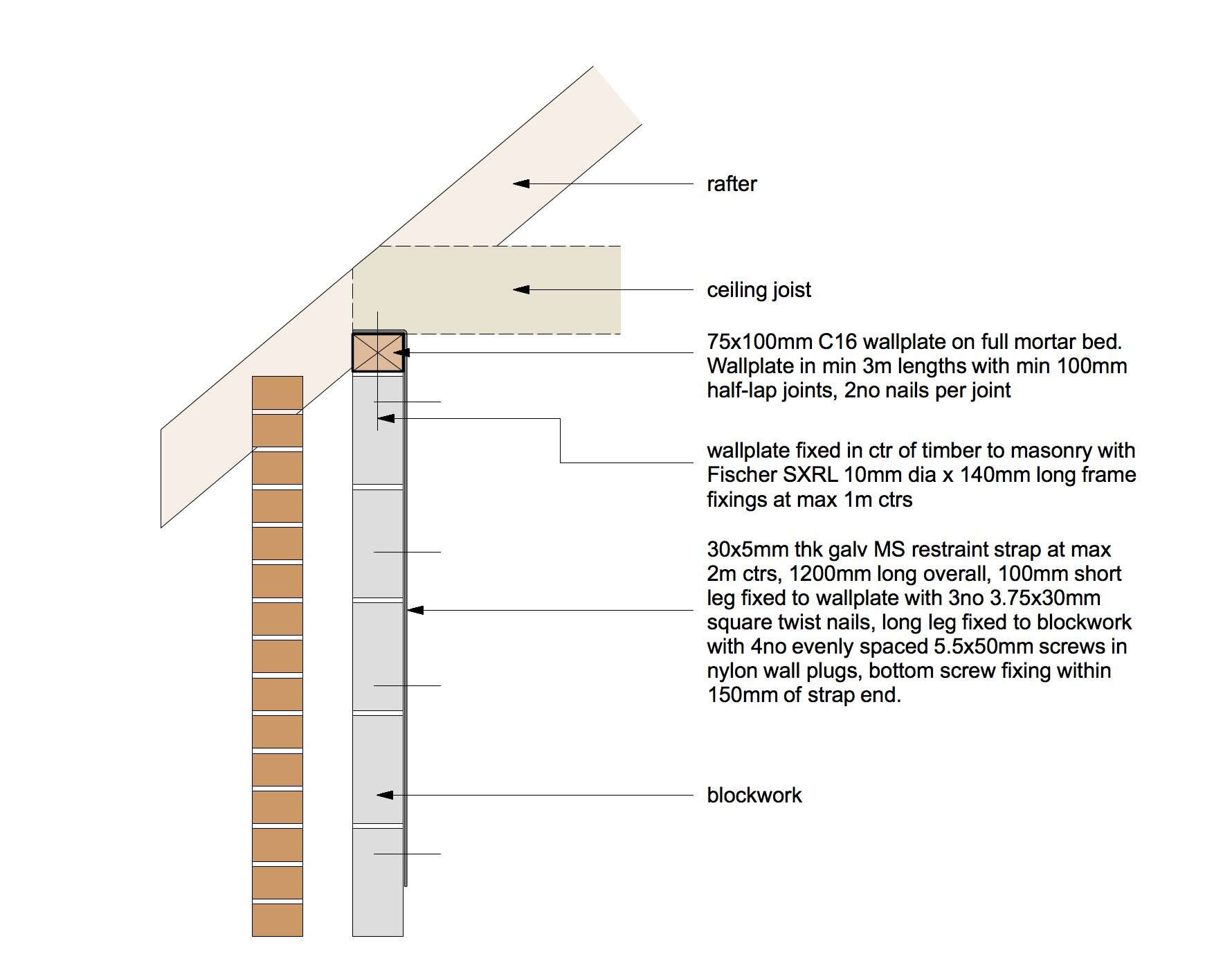

Section through wall plate

Specification:

Wall plate shall be 75x100mm C16 timber lined and levelled and set on full mortar bed and aligned with inner face of external wall. Wall plate shall be in min 3m lengths or, where shorter lengths are necessary, these shall be a single length extending across min 3no rafters. Joints in wall plate (including at wall corners) shall be min 100mm half-lap joints with 2no nail fixings. Wall plate shall be fixed to wall with Fischer SXRL10mm dia frame fixings 140mm long at max 1m ctrs in centre of wall plate, installed after mortar has set. Wall plate shall be strapped with 30x5mm galvanized steel L-shaped restraint straps at max 2m ctrs. Short leg of strap shall be 100mm long and fixed to top of wall plate with min 3no 3.75x30mm square twist nails. Vertical leg of strap shall be min 1m long fixed to inner face of wall with min 4no evenly spaced 5.5x50mm woodscrews in nylon wall plugs, lowest screw to be within 150mm of bottom of restraint strap. All fixings in masonry shall avoid mortar joints and be within middle-third of length/height of masonry unit.

This solution goes further than some of the guidance in certain respects:

The 75x100mm is larger than the guidance requires for the reasons previously outlined.

I have included frame fixings to fix the wall plate to the wall. These also provide a mechanical connection for lateral support. The fixing type, size and length must be compatible with the particular brick or block used.

I have included a 5mm thick tension strap rather than the 2.5mm thickness advised by the guidance documents. This is because there may be requirements for other restraint straps on the project, which must be 5mm thick. It makes practical sense to avoid confusion by only having one strap type on the project.

Although the guidance only requires the holding-down strap to be included in cases where wind uplift is an issue, I include it as a standard detail in all cases. This is because it’s such a simple, inexpensive detail that it’s not worth omitting it in other cases.

Is the wall plate structural?

The wall plate is more of a construction device than an element of the building structure. On the other hand, the holding-down strap is a structural component essential when there is a risk of wind uplift forces overcoming the roof's weight.

If you are working with a structural engineer, they will probably want to specify the wall plate, strapping details, and any other lateral support details required on the project. This will require co-ordination to ensure that you are both happy with the details and to agree on who specifies the detail - as it should either be in the architect’s documents or the engineer’s, but not both.

I prefer to include the details in the architect’s information while including a reference in the engineer’s specification.

Summary

As you have seen, there’s plenty of guidance on wall plates, but it isn’t comprehensive and can be confusing. Obtaining a clear understanding of the issues involved will give you confidence when detailing wall plates and inspecting works on site.

There are some lessons from having an in-depth look at wall plates which apply more generally to other aspects of construction detailing:

- Make sure you find and study the guidance!

- Ask other people how they would do the detail (colleagues, engineers, builders, suppliers, inspectors).

- But look at the guidance as well.

- If you find something confusing or that you don’t fully understand, don’t let it go.

- Ensure that your documentation is co-ordinated with the engineer's.

- Take account of how things actually happen on site.

If you ask around, you’ll probably find that people do things differently, so it’s worth discovering what guidance they have used and why they do things the way they do. Develop your views so that you can confidently make your own decisions.

Your knowledge of building construction will develop from understanding hundreds of small details like this one. It is hard to know where to start, so just start somewhere. Your expertise will build over time.

Post Script

I must thank structural engineer Ted Ruffell for adding the following:

Since most rafters are fixed by ‘skew nailing’, the wall plate must have sufficient depth to receive the nails.

In masonry construction, the ‘perps’ (perpendicular joints) can be more sensitive to load. This depends on the nature and strength of the mortar, but including the wall plate does help to protect these joints. In that limited sense, the wall plate distributes the load from the rafters.

Post Post Script

The post was updated to expand the holding down and lateral support section - the term ‘lateral support’ has been used instead of ‘lateral restraint’ to be consistent with the guidance.